You'll hear this one in team meetings, performance reviews, and KPI reports: DIFOT. It stands for Delivery In Full On Time, and it's one of the most important metrics in the logistics industry. If you've ever wondered how your company measures delivery success — and how your performance feeds into that measurement — DIFOT is the answer. Understanding it helps you understand what your employer actually values and how to keep your scorecard clean.

Breaking It Down

Delivery: The parcel reached the customer or delivery point. It wasn't returned, lost, or sitting in the depot.

In Full: The complete order was delivered. If a customer ordered three items and you delivered two because one was missing from your van, that's not "in full." Partial deliveries count against DIFOT even if the missing item wasn't your fault.

On Time: The delivery arrived within the promised timeframe. If the SLA (Service Level Agreement) says next-day delivery by 5pm and the parcel arrives at 5:15pm, it's late — even by 15 minutes. On time means within the window, no exceptions.

How It's Calculated

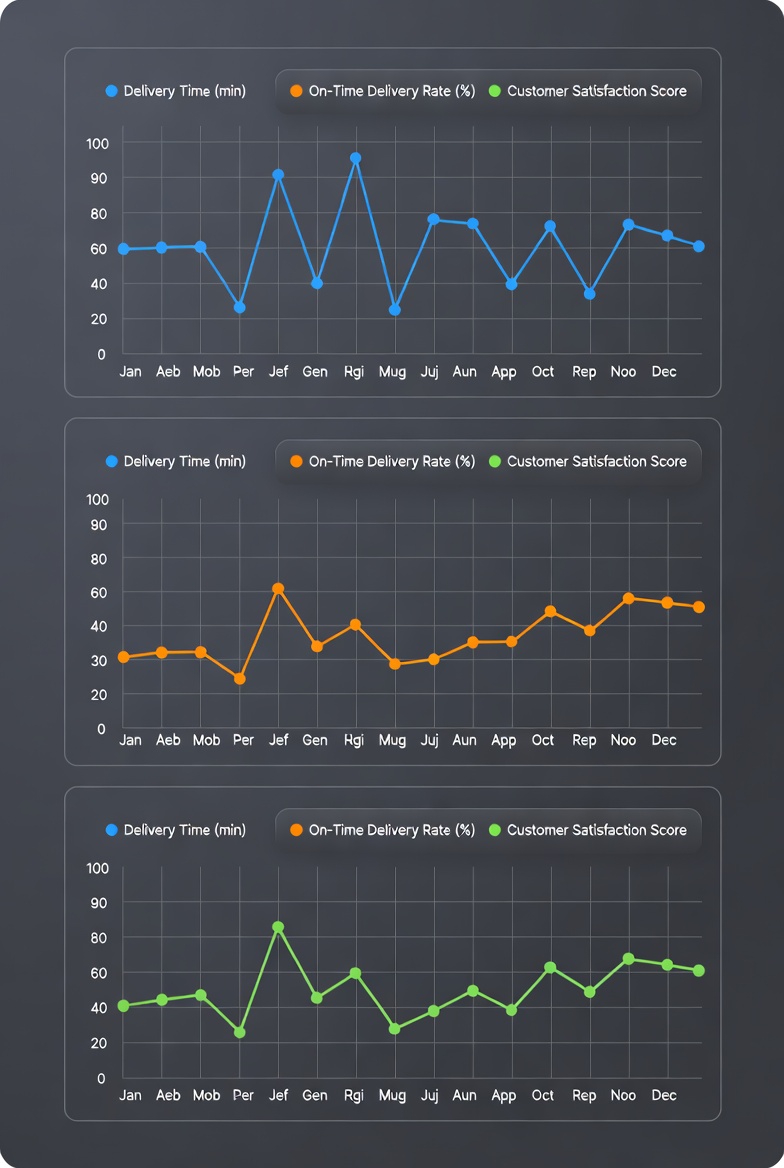

DIFOT is expressed as a percentage: (Number of deliveries that were in full AND on time) ÷ (Total number of deliveries) × 100. Industry benchmarks vary, but most logistics companies aim for 95%+ DIFOT. According to Supply Chain Sustainability School resources, supply chain performance metrics like DIFOT are used across the industry to benchmark operational effectiveness.

A 95% DIFOT on a 100-stop run means 95 deliveries were complete and on time. The 5 that weren't might include: a parcel that was missing from the van (not in full), a delivery that happened after the cutoff time (not on time), or a failed delivery attempt where nobody was home (not delivered).

What It Means for You

Your performance feeds into DIFOT. Every failed delivery, every late delivery, every parcel you bring back to the depot — they all reduce your company's DIFOT score. This is why supervisors care about completion rates, failed delivery codes, and whether you're finishing your run within the delivery window.

Not everything is in your control. A parcel that wasn't loaded onto your van, a customer who isn't home, an address that doesn't exist — these all hurt DIFOT but aren't your fault. Good companies distinguish between driver-controllable and non-controllable failures. Bad companies blame the driver for everything.

Scan codes matter. Using the correct failure code when you can't deliver is important for DIFOT analysis. "No safe place" is different from "wrong address" is different from "customer refused." Accurate coding helps the business identify where problems actually are — and keeps unfair blame off your back.

DIFOT drives contracts. Courier companies win and lose contracts based on DIFOT. If a retailer's SLA requires 97% DIFOT and your company delivers 93%, they lose the contract — and you potentially lose your run. Understanding DIFOT helps you understand why the business pushes for performance.